Over 2 years of history

300 authorized cooperative suppliers

Grakey owning a professional and mature team

Who We Are?

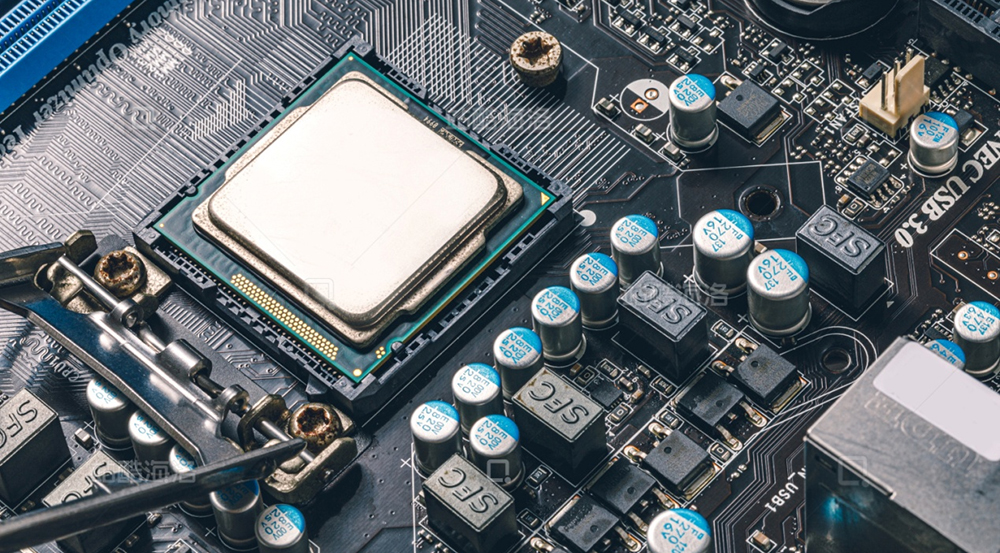

Grakey is an internationally renowned hybrid distributor of electronic components, specialize in a great variety of international famous brands of active and passive components which are widely applied in wireless communication, telecom equipments, enterprise network, digital media, home entertainment, automotive electronics, industry control and many other fields.. The company is located in Hong Kong and Shenzhen (China). We have our own warehouse and business service office. With our huge inventory, complete variety and leading professional technical support, we have become the preferred supply service partner of many well-known electronics companies around the world.

What We Do?

Professional agent distributes all kinds of discrete semiconductor devices (diodes, transistors, IBGT modules, field effect transistors) and integrated circuits (IC, memory chip) passive (tantalum capacitor, capacitor resistance) and electromechanical components (connectors, switching devices) and so on. We work closely with leading semiconductor suppliers worldwide to serve OEM plants at home and abroad. Businessmen, ODM manufacturers and EMS manufacturers provide a wide range of electronic components. Their applications cover wireless communications, telecommunications equipment, enterprise networks, digital media, home entertainment, automotive electronics, industrial control and many other fields.

Corporate Culture

Quality first, customer first. With integrity, enterprising, quality service for 2 years, with the basic development strategy, commitment to quality tracking ability and efficient professional global team cooperation. HongKong Grakey Technology provides you with satisfactory service based on integrity.

>>> Best service for you

Why Choose Us?

Grakey always carry out 'NEW & ORIGINAL. EFFICIENT & BEST SERVICE*, which is our core business concept since 2021.We serve for over 1000 global corporate buyers. 300 authorized cooperative suppliers, over 500000 part numbers online inventory after 2 years. By now Grakey has become one of the most valuable supplier of Electronic Components.

Our Team

With a professional and mature team and integrated management system of warehousing and authorized distribution, Grakey can offer suppliers, distributors and manufacturers one-stop service. We are deeply convinced that with the help of our one-stop service, every penny we save for you will turn out your competitive capital.

Viapart Quality Control

We investigate supplier credit qualification thoroughly, to control the quality since the very beginning. Grakey have its own QC team, can monitor and control the quality during the whole process including in-coming, storage, and delivery and etc

Contracted with the global authorities third party testing power, by using the most advance testing machine, each the high precision part is tested strictly to ensure that its stability and compatibility can meet its own specification.

Anti-static, moisture-proof and demage-prevetion method & package will be adopted strictly during the stock and delivery procedure. We undertake the responsibility to return or replace the parts which exactly have quality issues.

*Visual Inspection

*X-ray Inspection

*Marking Permanency Test

*De-capsulation Test

*Pin Assignment Test

*PB Free / RoHS Test

*Electrical Test

*Functional Test

The first, and most essential, step for any component evaluation is a thorough inspection process. Our procedure and acceptance standards have been developed in order to detect and report evidence of remarking, resurfacing, and refurbishing.

Marking permanency and resistance to solvents, resurfacing, dimension verification, marking code matching, high-power magnification inspection of body and terminal condition are standard methods within our inspection process. All inspections and observations are reviewed by Quality Engineers to evaluate whether we are seeing a new counterfeiting technique or a manufacturing anomaly.

Inspection and analysis of a component to examine hardware integrity and variations between devices within a population. Not all variations, however, mean a counterfeit device. Understanding the manufacturing process and how manufacturer supply chains and engineering controls operate, we can identify when variations are manufacturing-based rather than indicators of counterfeiting.

X-ray system is real-time and can rotate the object on all three axes for outstanding imaging capability and analysis of individual components and assembled boards.

A destructive test that removes the insulation material of the component to reveal the die. The die is then analyzed for markings and architecture to determine traceability and authenticity of the device. Magnification power of up to 1,000x is necessary to identify die markings and surface anamolies.

The spectrometer is used for measuring the controlled elements in lead-free and RoHS compliant devices and determining the composition of plating materials. We also use this equipment for helping to detect reconditioned and resurfaced parts by measuring the plating thickness and variations in the composition of the surface material.

Viapart Quality Control

This is not a counterfeit detection method as oxidation occurs naturally; however, it is a significant issue for functionality and is particularly prevalent in hot, humid climates such as Southeast Asia and the southern states in North America. The joint standard J-STD-002 defines the test methods and accept/reject criteria for thru-hole, surface mount, and BGA devices. Devices that are delivered in inappropriate packaging, acceptable packaging but are over one year old, or display contamination on the pins are recommended for solderability testing.